Watch printing technique

Watch Branding offers a wide variety of imprint processes to cater for the specific needs of our customers. Whether it’s branding your unique corporate identity, promotional merchandise or adding a personal message to commemorate a company anniversary gift, with the help of our 17+ years of experience we are able to get the level of customization just right.

These are the most common methods of personalization that we can easily implement. However, there are many more customization possibilities. Contact us to learn about all of the options you have when it comes to our imprint services.

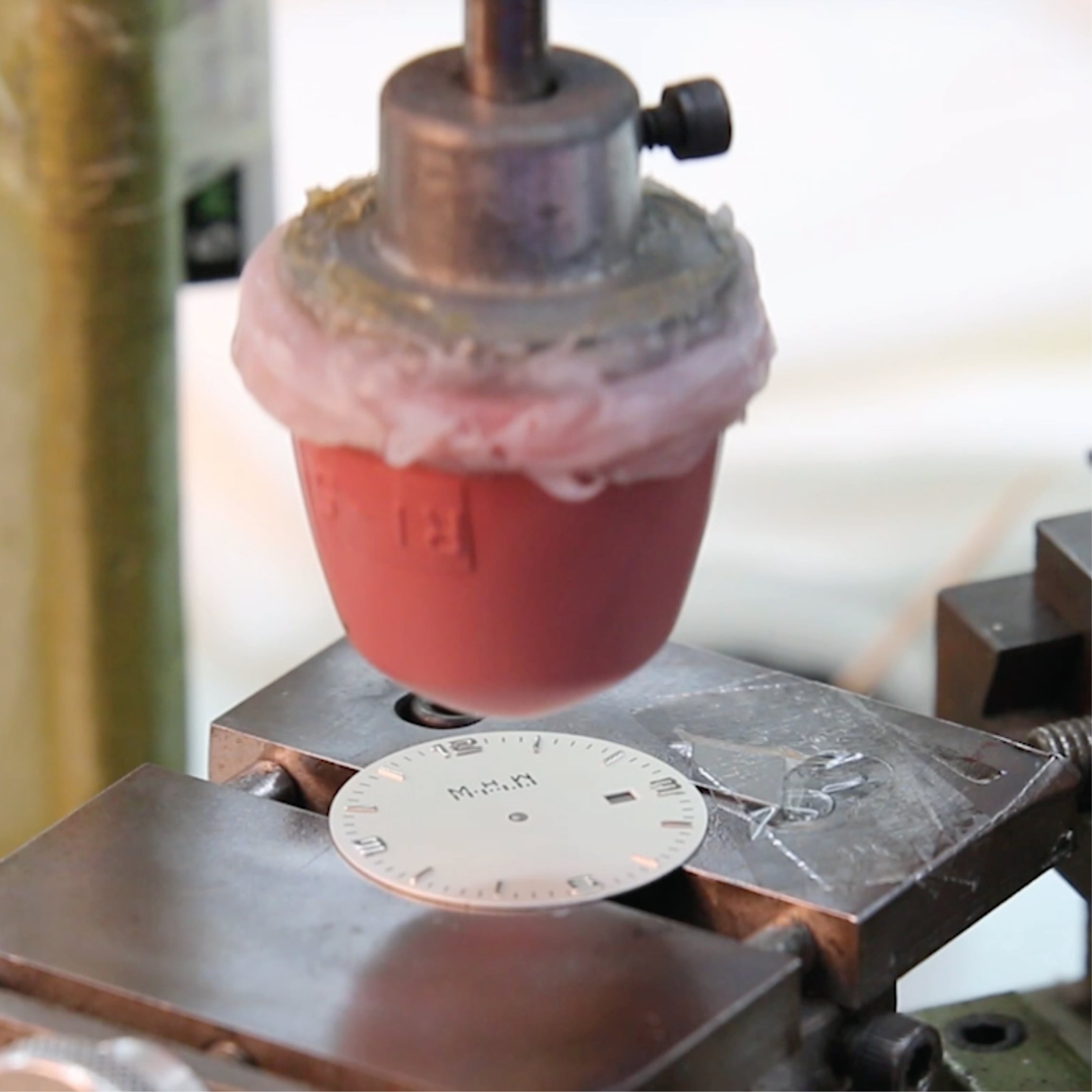

Padprinting

Pad printing ensures very sharp results, and has the advantage of a more dimensional print.

The principle of pad printing is using a silicone pad to pick up ink in the shape of the printing image from a steel image plate (called cliché) and then use the pad to transfer the picked-up ink onto the watch dial.

Due to the elasticity of silicone, any unevenness or texture on the watch dial does not affect the printing image. Our pad printing inks allows for a crisp, clear, vibrant imprint for any uni-color and multi-color logo or artwork. Using high quality pad printing equipment, any design can be accurately realized.

Raised logo on dial

Raised logo by process called UP/Tape transfer is a decoration technique that gives logos a super imposed metallic effect.

We can almost apply any company logo, brand name or special anniversary emblem in a raised effect on any watch dial texture. It can be made in almost any pantone color in a gloss or matt finish. The most used colors are silver, rose gold, black, gun and yellow gold.

This decoration technique is commonly used by small to large scale businesses that want to make their message more compelling.

Photo process on dial

To reproduce a photographic with gradual effect or painting-like image on a complete watch dial we use the photo process technique. This method will take any print to a new dimension.

Photo process is printing from a computer image file directly on photo paper, then the image will be cut into the size of the dial and through thermal pressure, the image will be applied on the watch dial. This type of personalization can only be used for analogue (two or three hand) watches. It’s not suggested to use this method on slim watches, because of the possible effect on the moving of the hands.

Digital print dial

This full colour printing (CMYK) process allows Watch Branding to personalize watch dials, using an almost unlimited range of colours, shades and gradients.

Direct digital printing uses modern inkjet technology to print directly onto the watch dial. The logo can be imprinted in almost any size (depends on the complexity of the watch dial) or location on the dial. Highly detailed or elaborate designs that require colour accuracy can be executed flawlessly using this printing method.

Laser engraving

This technology utilizes lasers to engrave – with high accuracy and with a high contrast- almost everything into the material that’s highly wear resistant. Imprints depth can be measured in a hundredth of a millimeter.

Within the watch industry laser machines are used for marking, serial numbers, individual numbers (eg 1/25 – 25/25), names (eg this watch is especially made for Herman), decorative markings such as logos and graphics on watch components such as watch case backs, crowns, case sides, buckles and oscillation weights. From easy and simple to the most complex ones.

Silkscreen Printing

Watch Branding offers custom silkscreen printing service for our watch boxes. The versatility and durability of screen printing is one of the main reasons why we use this printing method for our boxes.

Silkscreen Printing is a stenciling method that involves printing ink through stencils that are supported by a porous fabric mesh stretched across a frame called a screen. This printing process is ideally suited to print any brand name, company logo, anniversary logo, club logo or custom design directly onto the lid of our boxes.

Whether it’s one colour or full colour print or elegant or bold, you will be satisfied with the final result.